LOAD MORE

You're viewed 9 of 17 products

Daicel Pharma synthesizes high-quality Daptomycin impurities such as anhydro-Daptomycin, Daptomycin β-Isomer, Daptomycin Lactone Hydrolysis, isodecyl acyl isomer, and more. They help in the quality, stability, and biological safety analysis of Daptomycin. We also offer custom synthesis of Daptomycin impurities and supply worldwide.

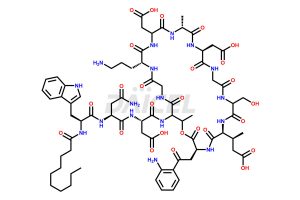

Derived from Streptomyces roseosporus, Daptomycin [CAS: 103060-53-3] is a cyclic lipopeptide antibiotic that effectively combats bacterial infections caused by Gram-positive bacteria, such as vancomycin-resistant enterococci (VRE) and methicillin-resistant Staphylococcus aureus (MRSA).

Daptomycin is approved for the treatment of complicated skin structure/ or soft-tissue infections (SSTIs) caused by Gram-positive bacteria in adult and pediatric patients. It is used in treating patients with Staphylococcus aureus bloodstream infections (bacteremia (including MRSA-methicillin- resistant strains)), and right-sided infective endocarditis.

The FDA has approved Daptomycin for administration through intravenous means. It is obtainable as a lyophilized powder for injection. Daptomycin is available in single-dose vials (concentration of 50 mg/ml). The single-dose vials are sterile, preservative-free, and pale yellow to light brown. The brand names under which Daptomycin is available are Cubicin and Dapcin.

The chemical formula of Daptomycin is C72H101N17O26, and its molecular weight is 1620 g/mol.

Daptomycin possesses a unique mechanism of action that is distinct from other antibiotics. It binds to bacterial membranes causing rapid depolarization of membrane potential. Further, the loss of membrane potential causes inhibition of proteins, DNA, and RNA synthesis, ultimately resulting in bacterial cell death.

During the synthesis of Daptomycin1, various impurities such as Daptomycin acid, dehydration product, N-Acetylated Daptomycin, etc., may form due to side reactions or incomplete reactions. The impurities formation during the synthesis of Daptomycin can be optimized by various processes such as controlling the reaction conditions, using high-purity reagents, and employing appropriate purification methods.

At Daicel, we offer more than fourteen types of Daptomycin impurity2 standards like isodecyl acyl isomer, Daptomycin β-Isomer, Anhydro-Daptomycin, etc. Further, we have the technology and expertise to prepare any unknown Daptomycin impurities or degradation products.

We provide a Certificate of Analysis (CoA) from a cGMP-compliant analytical facility for Daptomycin impurities with complete characterization data like 1H NMR, 13C NMR, IR, MASS, and HPLC purity. We provide 13C-DEPT and CHN on request. Also, we provide a complete characterization report upon delivery. Daicel offers highly pure isotope-labeled standards of Daptomycin in bioanalytical research and BA/BE studies with isotope data in CoA.

Daptomycin is extracted from the fermentation broth, purified, and then subjected to derivatization reactions to create impurities. The impurities are characterized using analytical techniques. The manufacturing process must adhere to strict regulatory guidelines to ensure the safety and efficacy of the final product.

Daptomycin impurities are detected using analytical techniques such as high-performance liquid chromatography3 (HPLC), liquid chromatography-mass spectrometry (LC-MS), etc. These techniques can identify and quantify impurities in the drug product.

Different measures are taken to control Daptomycin impurities that include optimizing the synthesis and purification process, controlling environmental factors such as temperature and humidity, and monitoring the drug product throughout its shelf life. These measures aim to minimize impurities levels and ensure the drug's quality and safety.

Note: Products protected by valid patents by a manufacturer are not offered for sale in countries having patent protection. The sale of such products constitutes a patent infringement, and its liability is at the buyer's risk.